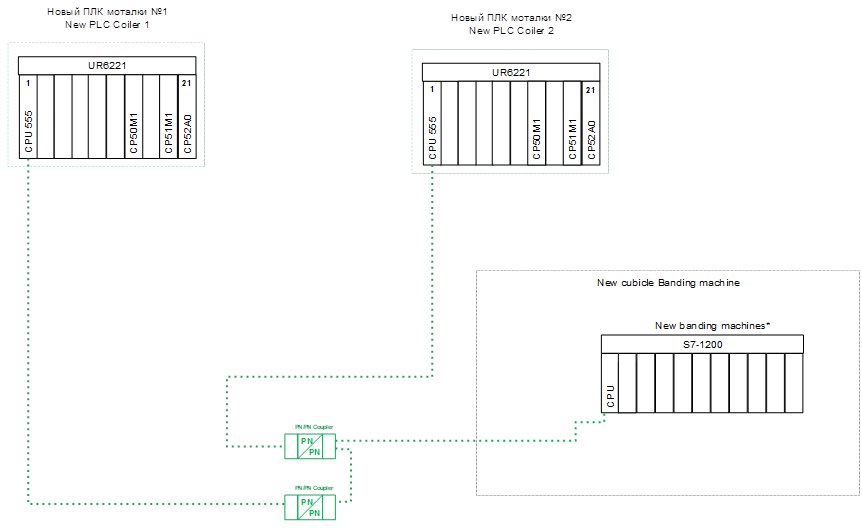

1. Communication of the PLC of this strapping machine with a production line or other system is provided by Profinet or Ethernet cables.

Communication of the PLC with the Ethernet plant network can be done via IE (an additional communication module will be required). The communication with the production line PLC can be done via Profinet via PN-PN Coopler. Ethernet and Profinet must not be physically connected!

Nothing is said about remote I/O stations. Must be ET200SP.

2. Imaging System

The system is monitored by WinCC and the software will be installed on the following operator panels:

None.

Must be:

ARM on PU-9 perform as a “thin” client (when implementing through WinCC, not included in the TIA Portal) with industrial Touch monitor with a diagonal of at least 19 “, when implementing SCADA system through TIA Portal use fanless PC with DIN rail mount, monitor mounting should be done on the left rack of the new coil control panel.

Connect the PLC and automated workstation to the existing technological Ethernet network of the LPTs-2.

Provide in the delivery set a workstation with software for setting up and parameterizing the equipment.

The machine is designed to tie a bale on a conveyor with walking beams, not on a cradle skimmer.

The machine moves along the axis of the bale, in our case it has to be stationary, there is no room to move.

The sliver feeding guides move only horizontally, in our case we also need the vertical movement (approach to the coil), indicated by arrows, so in the strapping cycle time for this movement is not taken into account.

There is no opening the upper part of the frame to remove the coil (it is assumed that the machine will depart, but in our conditions it is not possible).

Welding head is on the wrong side of the connection with the notch is in the 13:00 – 15:00 hour position, we need at 9 o’clock

A compressor station must be included in the delivery, we will not be able to provide the air requirements

Коллеги, прошу Вас заполнить коммерческую таблицу (во вложении).

Она будет являться Вашей офертой на тендере.

Отправляю комментарии по технической части.

Ожидаем ответ в виде скорректированного предложения и таблицу 21.10.2022.

Связь ПЛК данной обвязочной машины с производственной линией или другой системой обеспечивается за счет кабелей Profinet или Ethernet.

Связь ПЛК с цеховой сетью Ethernet выполнить по IE (потребуется дополнительный коммуникационный модуль). Связь с ПЛК производственной линии выполнить по Profinet через PN-PN Coopler. Сети Ethernet и Profinet не должны физически соединятся!

Ничего не сказано про станции удаленного ввода/вывода. Должны быть ET200SP.