Determine your wrapping needs: Before you start shopping for a stretch wrapper, it's important to assess your specific wrapping needs. Consider the size and shape of the products you'll be wrapping, the number of loads you need to wrap per day, and the amount of space you have for the stretch wrapper. This will help you narrow down the options and choose a stretch wrapper that is well-suited to your needs.

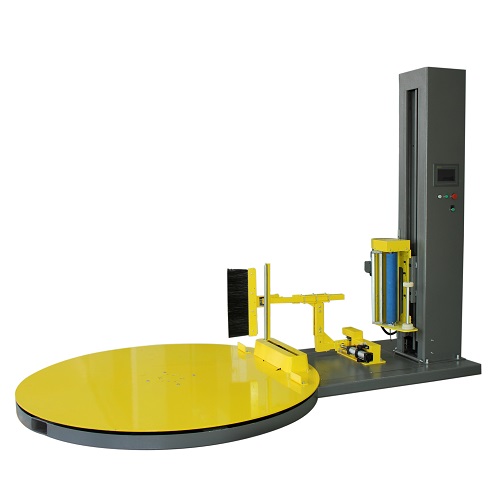

Consider the type of stretch wrapper: There are several types of stretch wrappers to choose from, including turntable, rotary arm, and orbital stretch wrappers. Turntable stretch wrappers are the most common and work by rotating the load on a turntable while applying stretch film. Rotary arm stretch wrappers rotate the film around the load, while orbital stretch wrappers move the film in an orbital motion around the load. Each type has its own advantages and disadvantages, so it's important to consider which is best for your needs.

Look for a stretch wrapper with user-friendly controls: You want a stretch wrapper that is easy to operate and maintain. Look for a stretch wrapper with user-friendly controls, clear instructions, and easy-to-access maintenance points.

Choose the right film for your needs: There are several types of stretch film to choose from, including hand stretch film, machine stretch film, and pre-stretched film. Hand stretch film is the most common and is applied manually using a hand dispenser. Machine stretch film is applied using a stretch wrapper and is typically more efficient and cost-effective. Pre-stretched film is stretched before it is applied to the load, which can reduce the amount of film needed and save on material costs.

Train your employees on proper stretch wrapping techniques: It's important to train your employees on proper stretch wrapping techniques to ensure that the loads are wrapped correctly and securely. This includes using the correct amount of film, applying the film evenly, and securing the film properly.

Maintain your stretch wrapper: Regular maintenance is key to keeping your stretch wrapper in good working condition. Follow the manufacturer's recommended maintenance schedule and be sure to address any issues that arise as soon as possible. This will help ensure that your stretch wrapper is working at its best and will help extend its lifespan.