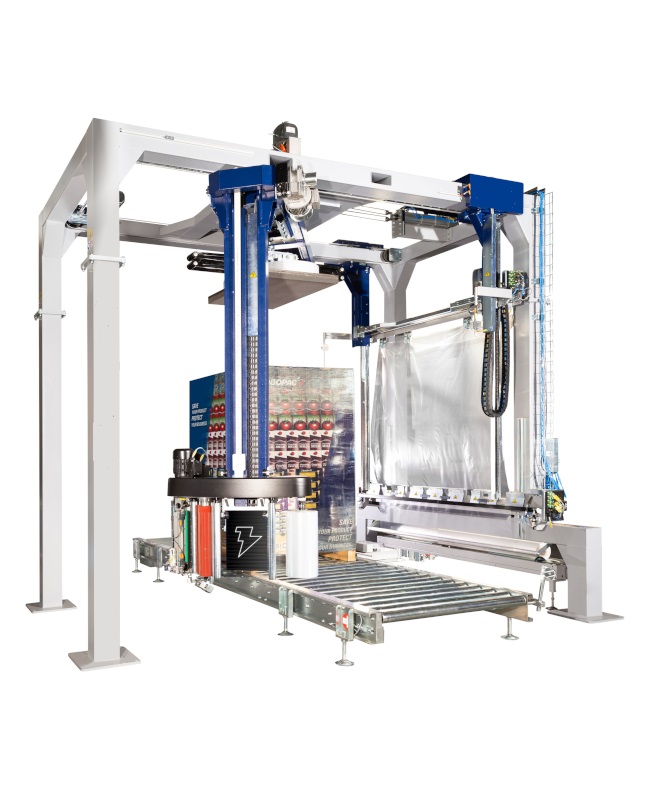

Rotary stretch wrap turntable is a high-speed machine that is capable of wrapping up to 90 pallet loads per hour. This makes it well-suited for demanding applications that require fast and efficient stretch wrapping. The machine operates at a speed of 36 RPM and is available with a range of useful options, including a 30″ film carriage, roping, top cover placement, top pressure hold down, pallet lifter, and auto corner board placement. These options likely allow users to customize the stretch wrapping process to suit the specific needs of their products, ensuring that they are securely and effectively wrapped for transport.

Rotary stretch wrap turntable is equipped with a range of advanced features that are designed to help users wrap products efficiently and effectively. The multi-level variable pre-stretch feature is intended to help users achieve the best film economy and can reportedly result in film savings of 30-55%. The multi-level variable containment force feature is designed to deliver optimal containment force at each level of the load, helping to ensure that it is securely wrapped. The pro-active rotary ring wrapper corner compensation feature is intended to enable users to wrap any load securely without damaging the corners or experiencing repetitive film breaks. The strategic film placement feature allows users to place the film exactly where it will have the most impact on load stability and containment. These features are likely intended to make the stretch wrapping process more efficient, effective, and reliable.

Rotary stretch wrap turntable is equipped with a film band reduction feature that uses an air blower device to seal the initial edge of the film within the wrapping. The device is designed to guarantee a perfect finish on the end edge of the film through electronically controlled impulse sealing on constant film thickness. The final sealing of the film is completed on a mechanical support, which helps to avoid direct contact with the product and ensures a clean and professional finish. These features are likely intended to make the stretch wrapping process more efficient and effective, as well as help ensure that the wrapped product has a professional appearance.

Contact:

www.fhopepack.com